About Traditional Facing Stone

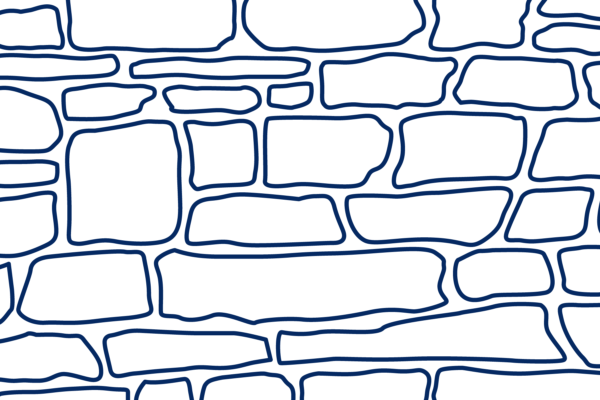

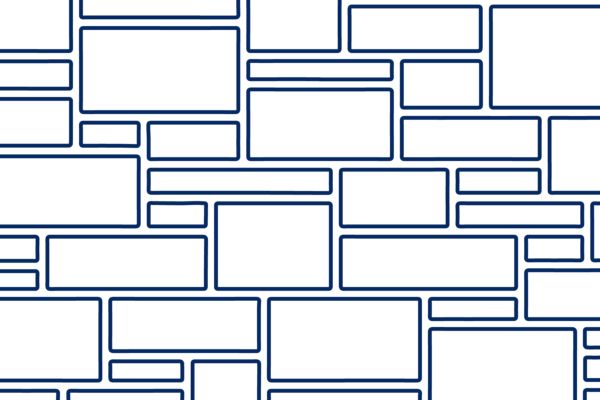

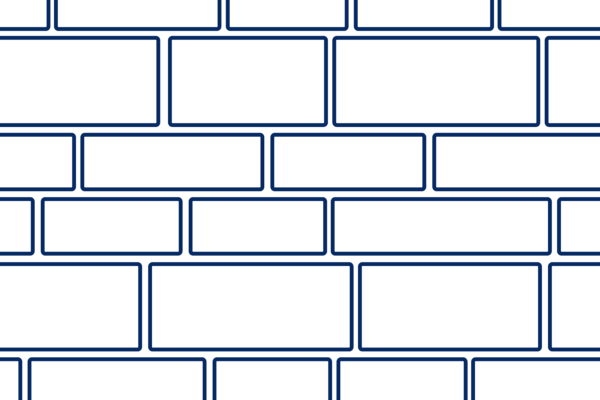

Full thicknessTraditional facing stone is full sized pieces of solid stone, available as cropped building and walling stone in rubble, random, semi-coursed and coursed styles. Our natural solid stone is for mainly used for exterior walling.

Our traditional facing stone is cropped to the bed width of the chosen build style, and has at least one usable face. Our natural stone walling is quarried predominantly in the UK and some Ireland. Available in a variety of regional colours, this enhances our range of natural stone giving us the largest selection choice. Our traditional facing stone is ideal for all exterior stone walling; it is durable, low maintenance, and weathers beautifully.

Traditional Facing Stone

Quoins and cornerstones can be cropped from any of our natural stone products

Traditional facing stone respects the unique architectural heritage of local areas

Natural stone is timeless and durable: it ages gracefully and weathers beautifully

Traditional Facing Stone for Exterior Walling

- 100% natural stone

- Unique: no two pieces of stone are identical

- Low maintenance: ages and weathers beautifully

- Durable: outlasts brick, render and timber

- Source: predominantly UK quarries

- 4 build styles: Rubble, Random, Semi-coursed Coursed

- Wide range: over 40 combinations of stone, colour and finish

- Full thickness: between 100-150mm depending on chosen style

- Suitability: ideal for all exterior building and walling

- Complementary products: quoins/corners for all facing stone

- Benefit: adds character, heritage, style and quantifiable value

Most popular Facing Stone

Traditional facing stone: the benefits

Suitability: ideal for building and walling for residential houses and properties, commercial and public buildings

Durability of stone enables natural stone buildings to last for hundreds of years. Traditional stone facing outlasts brick, render and timber indefinitely

Respect for the unique heritage of local areas: reflects vernacular architecture authentically yet cost-effectively

Natural beauty: the inherent diversity of colouring, texture and pattern within natural stone makes it one of the most beautiful and timeless materials to work with

Reduced environmental impact: working with natural stone is relatively non-toxic and low carbon compared to most other building materials. Since most of our stone is quarried in the UK and Ireland, our transport emissions are also relatively low

Support for traditional craftsmanship: due to the unique sizes and shapes of traditional facing stone, building with these materials often requires the skills of an experienced stone mason. We’re delighted to be able to promote and sustain these traditional skills on our projects

Planning permission: local planners usually respond positively towards proposals that help reflect and restore traditional and local architecture, including local stone heritage

Choice of traditional and contemporary styles and finishes, with a wide range of natural stone available in sandstone, limestone, slate and quartzite

Largest range of British natural stone: we pride ourselves on working with local quarries to maintain historical traditions

Frequently asked questions

-

Can you use the facing stone as a double skinned wall?

We don’t recommend this, most of our stones have one useable cropped face and we recommend a backing to support the stone.

-

How will my facing stone arrive?

All our facing stone gets put into our bulk bags. Our bags are around 850mm x 850mm x 850mm and approx. hold around 900kg.

-

What is facing stone?

Facing stone is just like building and walling stone, we use the term facing stone as we crop all our stone to a certain bed width, as we have large industrial Steinex croppers the cropper teeth along with the natural split of stone can give a tolerance, therefore we call it facing stone as we do recommend our stone has a backing support to it.

-

Shall I book my builder in before ordering the stone?

No, we recommend you ordering the product and have the items on site before organising the builder. This is to avoid any delays either with the product/s or delivery. We will not be held as liable for any changes relating to delays of tradesmen work.